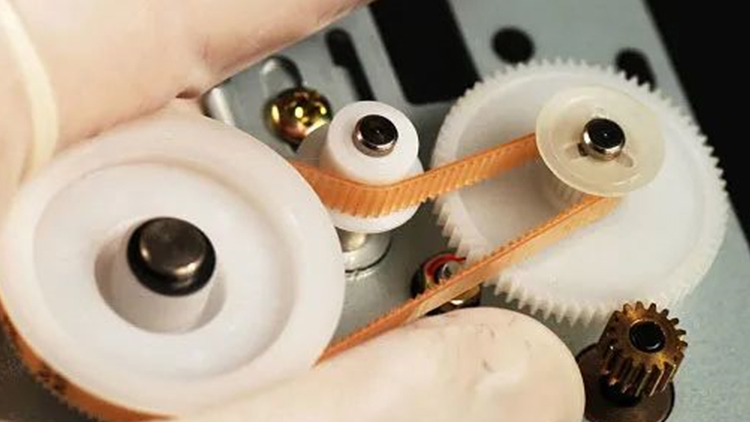

Anatomy of a gear machining process

Gear machining is an extremely complex process that can only be made possible through the use of the right techniques, and every part of the production process must also be dimensioned to an extremely precise level.

The gear machining cycle includes general turning → hobbing → inserting → shaving → hard turning → grinding → honing → drilling → bore grinding → welding → measuring, it is particularly important to have the right clamping system for this process, we will then introduce the gear clamping system for each process.

(1) General Turning

In general turning, the gear blanks are usually clamped on a vertical or horizontal turning machine. For automatic clamping, the majority of fixtures do not require an auxiliary stabiliser on the other side of the spindle.

(2) Hobbing

Because of its outstanding economy, hobbing is a cutting process used in the production of external gears and cylindrical gears. Hobbing is used not only in the automotive industry but also in the manufacture of large industrial transmissions, provided that it is not limited by the external contours of the workpiece being machined.

(3) Tooth insertion process

The gear shaping process is mainly used in cases where hobbing is not possible. This process is mainly used for the machining of internal gears and for the machining of external gears that are subject to structural interference.

(4) Shaving process

Shaving is a finishing process for gears, cutting with a cutter body corresponding to the tooth shape of the gear. This process is highly economical to produce and is therefore already widely used in industry.

(5) Hard turning

The hard turning process makes it possible to replace the expensive grinding process. In order for this to work properly, the various parts of the system and the machining section are connected together correspondingly. The selection of the correct machine tools and fixtures and cutting tools determines the turning results.

(6) Tooth grinding

In order to successfully achieve the necessary accuracy in gear production today, hard finishing of tooth faces is essential in many cases. A very cost effective way of machining in mass production. On the other hand, similar to prototype machining, gear grinding offers greater flexibility when an adjustable grinding tool is used.

(7) Honing process

Honing is a process for the final finishing of hard gears using amorphous cutting angles. Honing is not only highly economical, but also results in a smooth surface with low noise levels for the gears being machined. The low cutting speed (0,5 to 10 m/s) of honing compared to grinding prevents the gears from being machined with cutting heat. More precisely, the internal stresses generated on the machined tooth surface have a certain positive effect on the load-bearing capacity of the equipment.

(8) Drilling

Drilling is a rotary cutting process. The axis of rotation of the tool and the centre of the hole to be machined are in exact coincidence in the axial direction, and are in line with the direction of feed of the tool in the axial direction. The spindle of the cutting movement should be aligned with the shi tool, independent of the direction of the feed movement.

(9) Bore grinding

Bore grinding is a mechanical process with an amorphous cutting angle. Compared to other cutting processes, grinding has the advantages of high dimensional and forming accuracy for hard metals, dimensional accuracy (IT5-6), very small tremor marks high surface accuracy (Rz=1-3μm), etc.

(10) Capacitor discharge soldering

Capacitive discharge welding is a resistance welding process. Capacitive discharge welding is achieved by a very rapid increase in current, a fairly short welding time and a very high welding current. Capacitive discharge welding therefore offers many advantages. The economical and efficient nature of capacitive discharge welding is particularly important in view of the increasing energy prices.

(11) Measurement

The inspection of gears is very extensive and its has to be adjusted to the different forms of gears. In the measurement of gears, the different important parameters of the gears are determined by length, angle measurements and special gear process measurements.