About Hongpeng

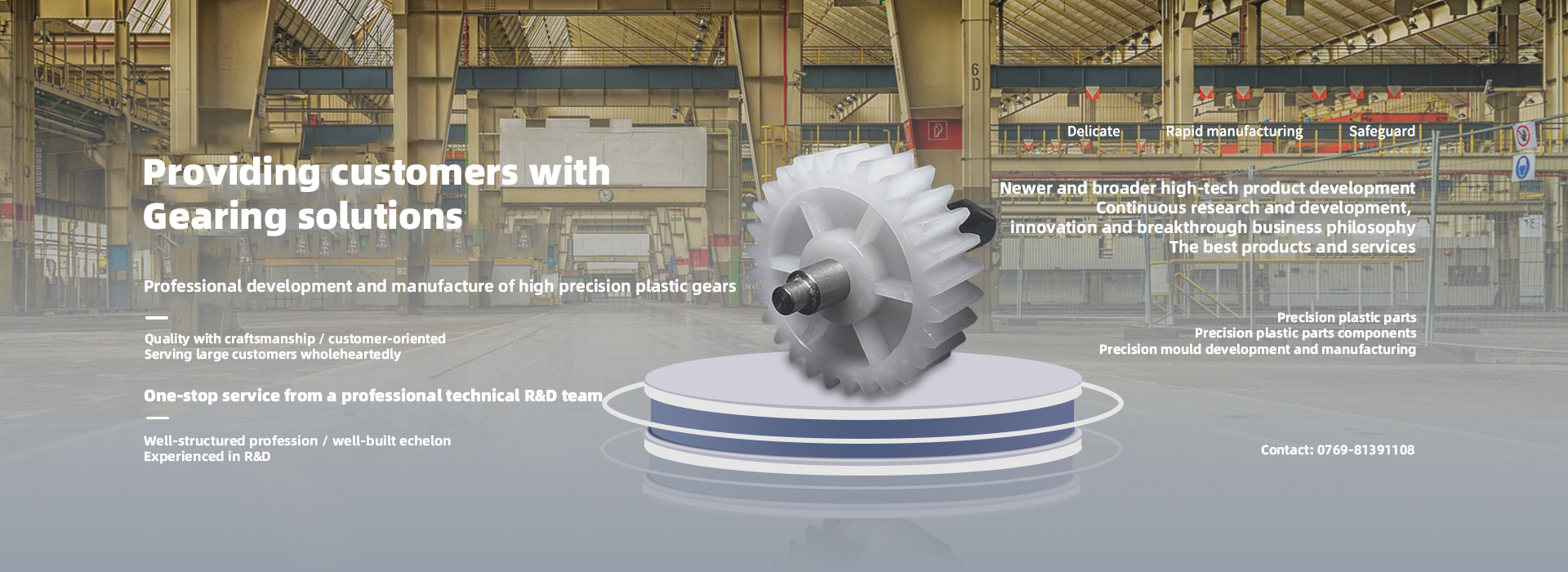

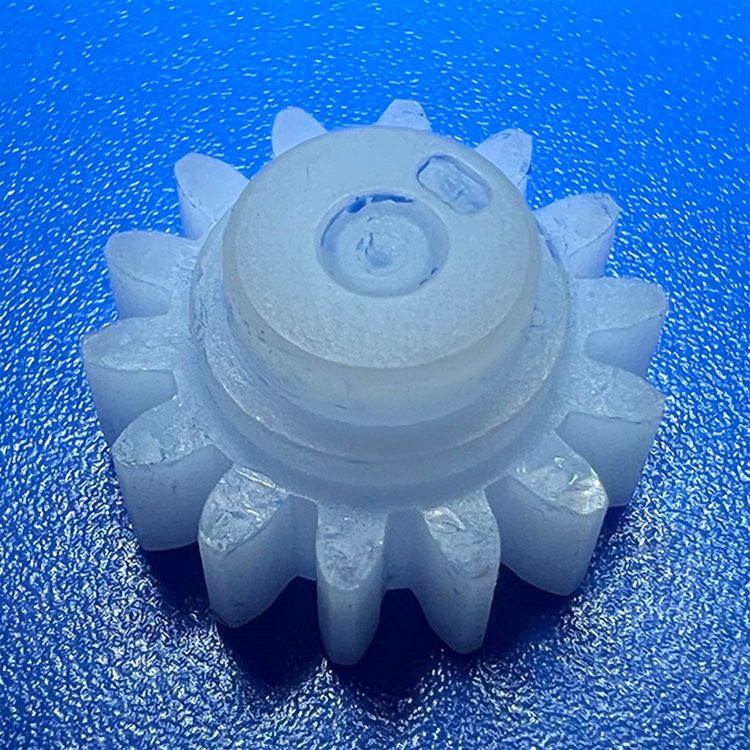

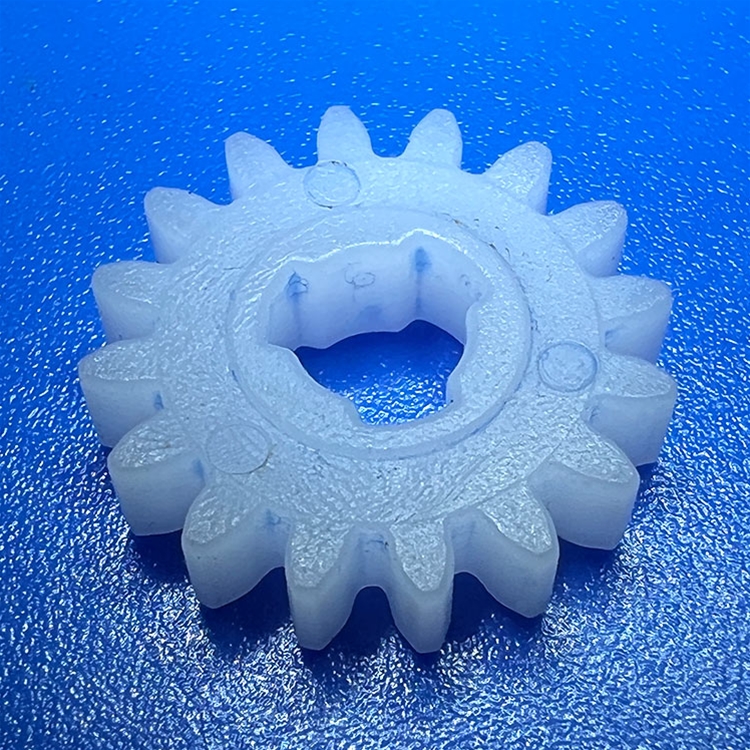

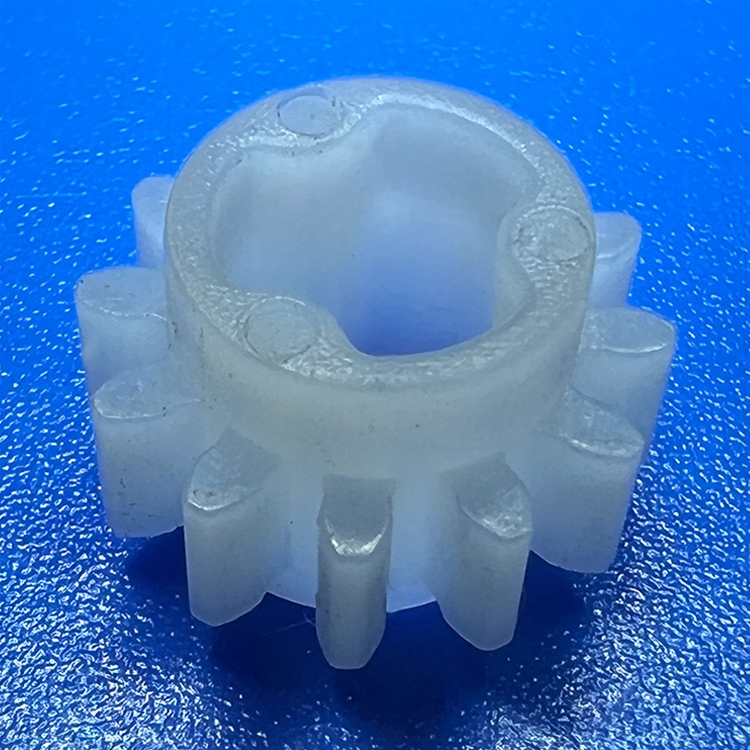

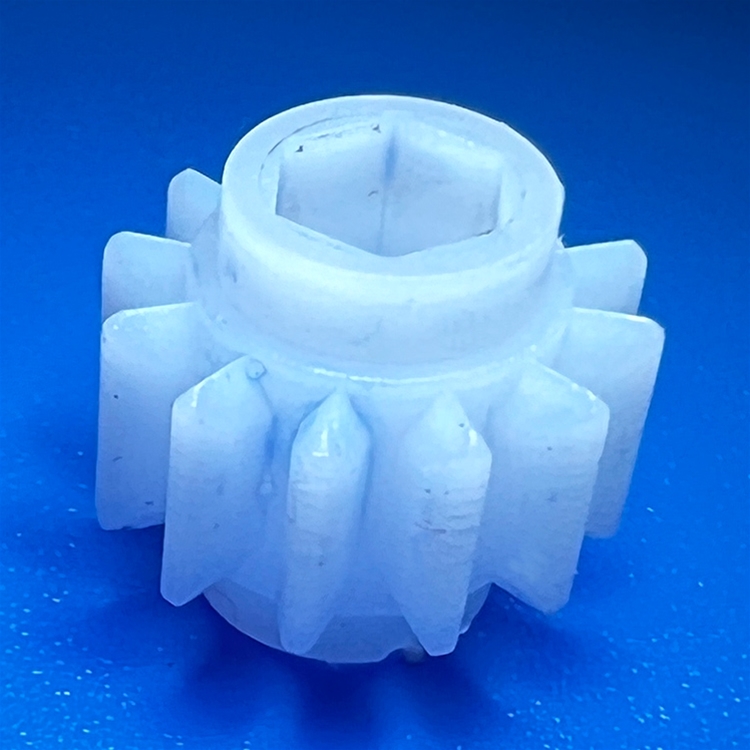

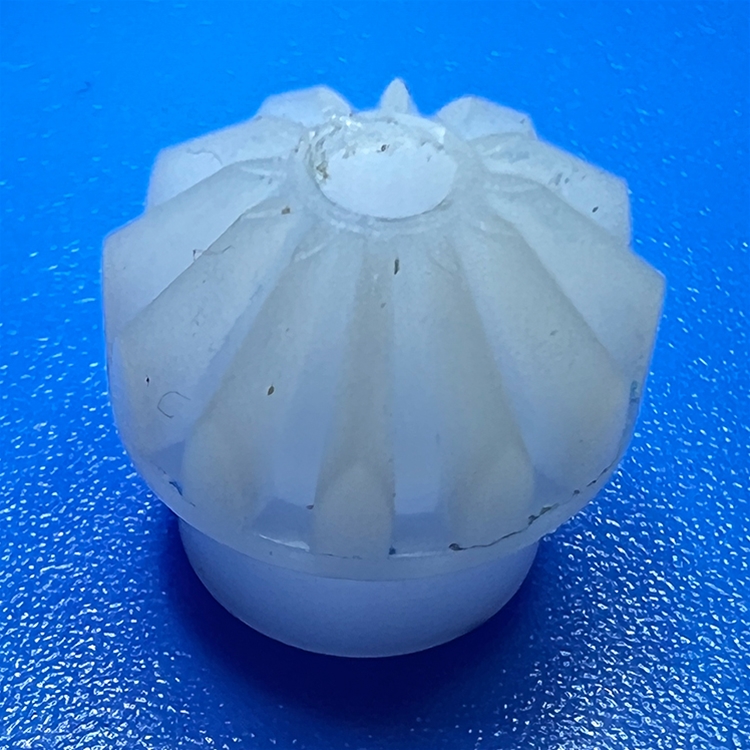

Founded in 2010, Hongpeng is a national high-tech enterprise dedicated to the production of precision plastic parts, components and precision mold development and manufacturing. The main products produced are plastic precision gears, precision structural parts, mold tooling and precision parts. They are widely used in office equipment, digital electronics, medical equipment, home appliances, auto parts, instruments and clocks, communication equipment, etc.

Dongguan Hongpeng Plastic Technology Co., Ltd, with registered capital of RMB 12 million, moved to No.2 Dongfeng 2nd Road, Xiasha 3rd Industrial Zone, Shipai Town, Dongguan City, China in May 2016.

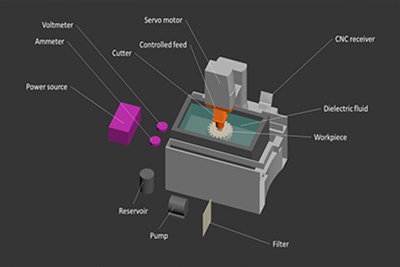

The company is a 5-story single building factory with a total area of 18,000 square meters. It has 50~260 tons injection molding machines, high-speed CNC machines, precision EDM machines, fine engraving machines, precision grinding machines, high-precision slow-walking wire, milling machines and other mold-making equipment, and its total assets reach 50 million RMB.

In 2021, the company applied for a provincial technical reform project to add new plants and equipment, with a planned investment of 50 million yuan.

At present, the company employs more than 200 people, integrating product development, design, production and sales, specializing in the production of precision plastic molds, injection molding precision plastic parts.

In 2015, the company passed ISO9001 certification and in 2022, it has passed IATF16949 certification; currently it is planning to implement ISO13485:2016 and ISO 14000 for environmental management system.

-

2010Year

Company established

-

200More than

Scientific Research Technology

-

1000More than

Clients Served

-

12million

Registered Capital

product

-

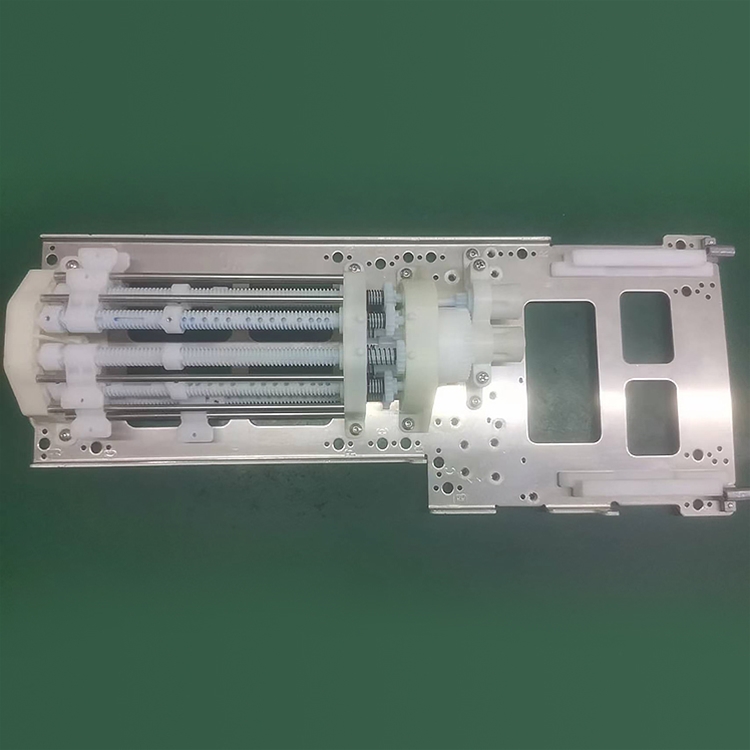

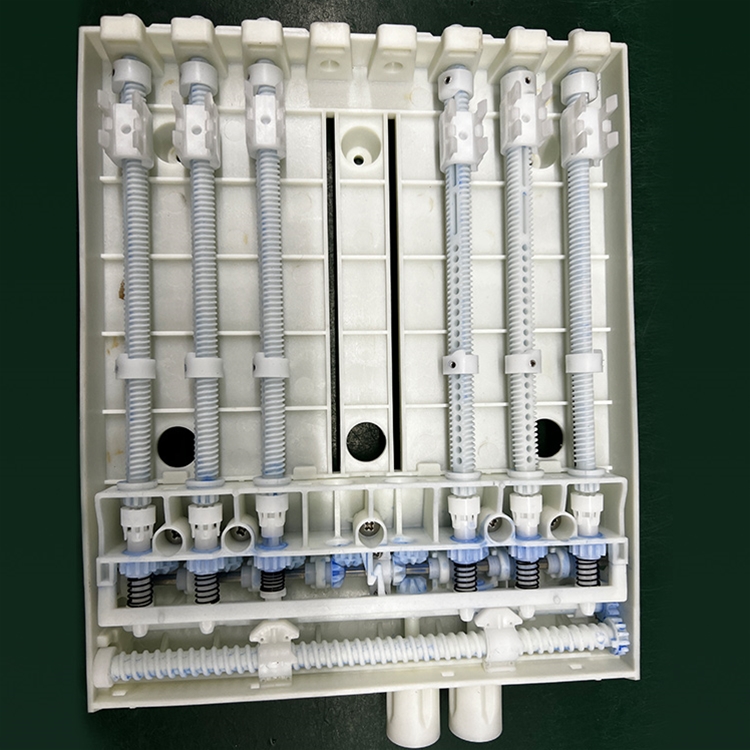

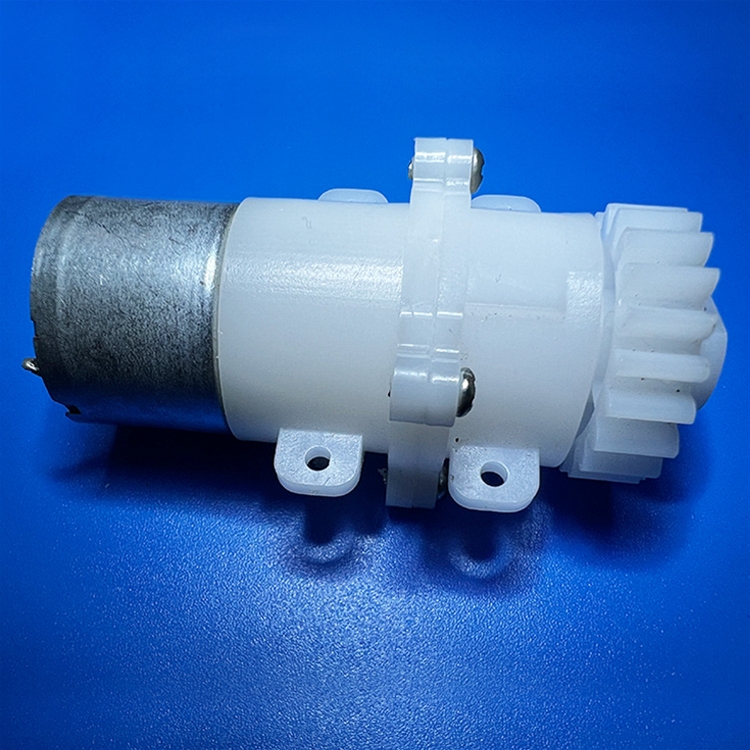

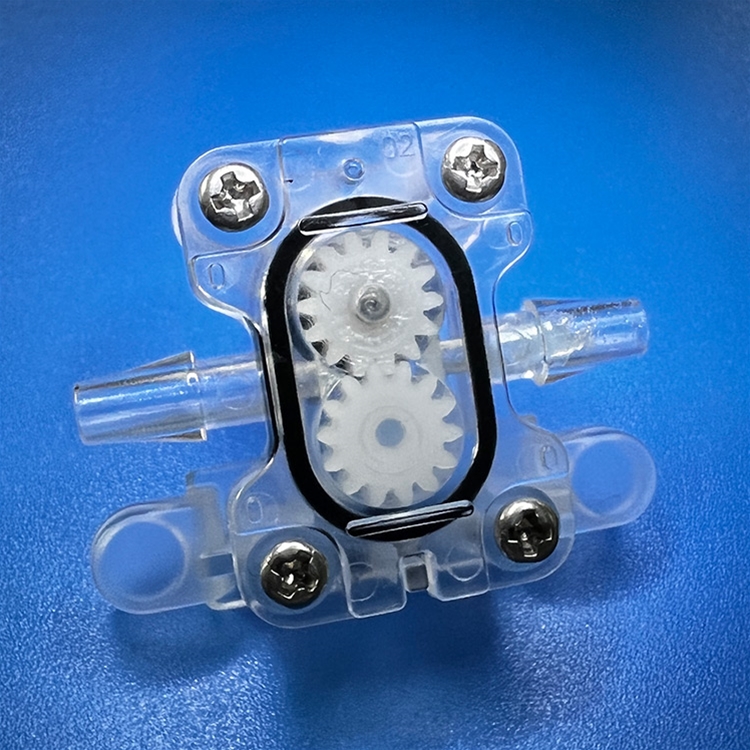

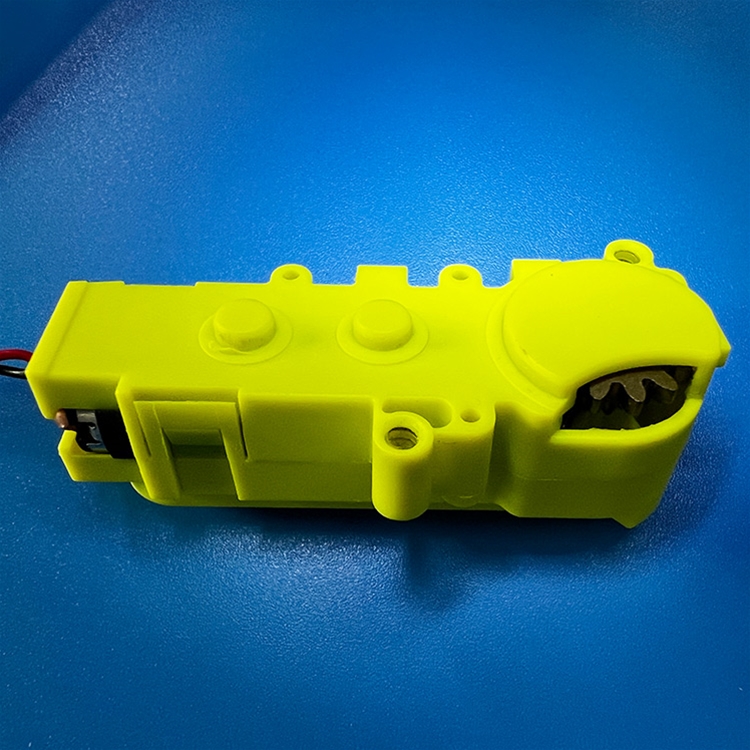

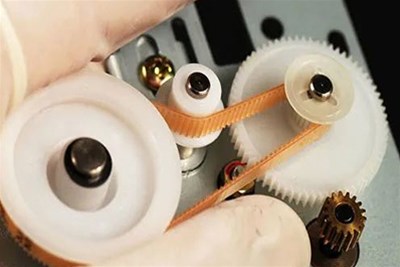

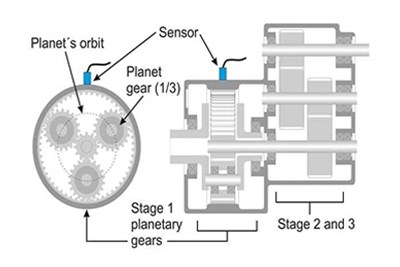

Plastic precision gear assembly production

-

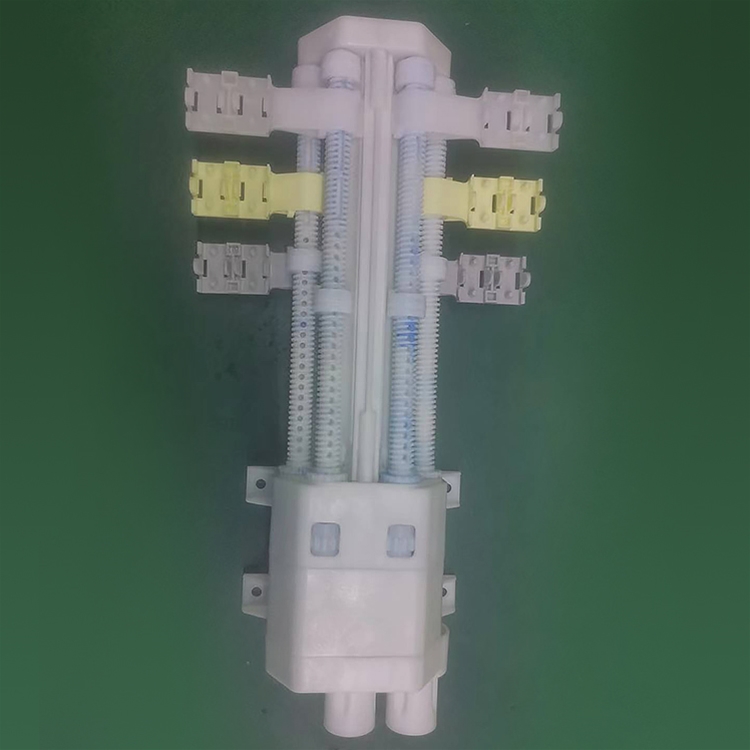

Plastic precision gear assembly injection moulding

-

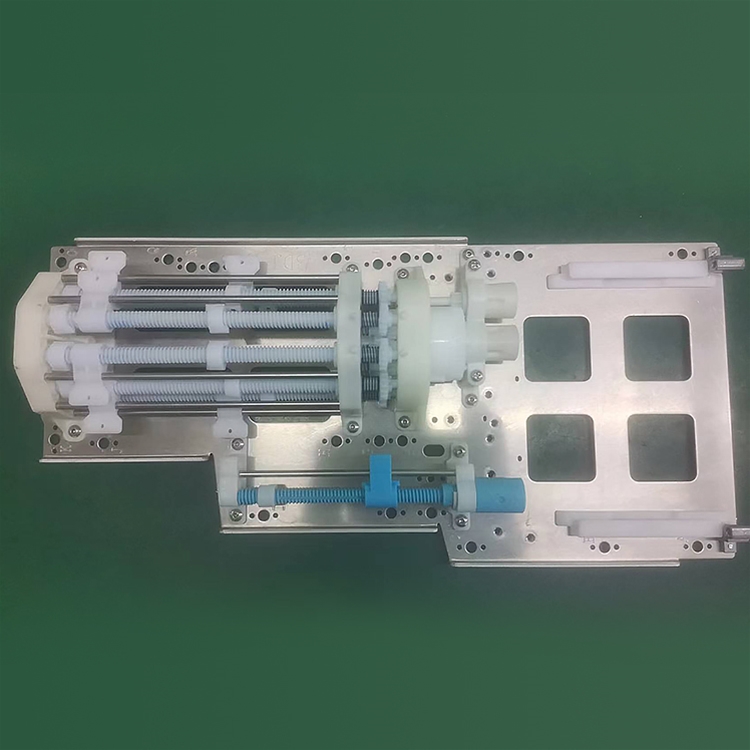

Plastic precision gear assembly manufacturing

-

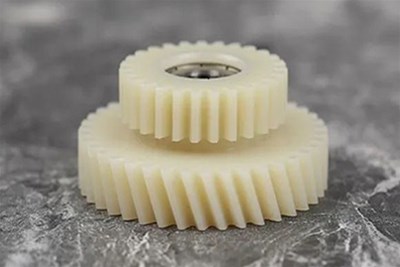

Nylon precision gear assembly

-

Plastic precision gear assembly modulus

-

Plastic precision gear assembly applications

-

Plastic precision gear assembly machinery

-

Plastic precision gear assembly construction

Corporate image

- Company News

-

Plastic gearing features and c…

2022-11-28Gearing is one of the most widely used transmission methods in mechanical transmission parts, and plastic gears, as one of the gear products, are more and more widely used in various fields because of their light quality, low transmission noise, high temperature resistance of gears, and their abilit…

-

Key points in the manufacture …

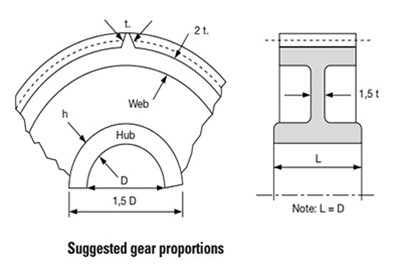

2022-11-28Precision gears are gears with very high dimensional and performance requirements. Parameters include: top circle outer diameter, root circle outer diameter, module, index circle diameter (also known as the common normal), index circle tooth thickness, pressure angle, skew angle, tooth runout tolera…

-

Plastic gear mould design stru…

2022-11-28In recent years, precision injection moulding, represented by plastic gears and transmission system components, is developing rapidly. Relying on strong technology and the concept of quality as the lifeline, Hongpeng has made a flourishing development in the field of precision transmission systems a…

-

Anatomy of a gear machining pr…

2022-11-28Gear machining is an extremely complex process that can only be made possible through the use of the right techniques, and every part of the production process must also be dimensioned to an extremely precise level.

-

Gearing noise reduction measur…

2022-11-28To ensure the quality of raw materials, the materials commonly used for manufacturing gears are 40Cr, 20CrMnTi, 40CrNi and other alloy steel and 45 steel. In order to ensure the quality of raw materials, we adopt the method of fixed point purchase, the purpose of which is to facilitate timely adjust…

-

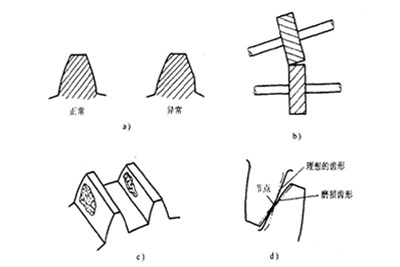

Analysis of common gear drive …

2022-11-28The manufacture of gears usually produces eccentricity, circumferential error, base joint error, tooth shape error and several other typical errors. There are many reasons for these errors, including errors from the machine tool movement, errors in the cutting tool, the tool, the workpiece, improper…

QUESTION

-

Q Which material …

AABS plastic and LDPE materials usually do not meet the performance requirements of plastic gears in terms of lubricity, fatigue resistance, dimensional stability as well as heat resistance, creep resistance and chemical corrosion resistance. However, they are also used in the field of low-grade sporting transmission gears such as various toys.

-

Q What to look fo…

AAs we all know, one important point to note when choosing a plastic gear grease is the need for good compatibility between the plastic parts and the grease. This is why compatibility tests are carried out before new products are officially used. When choosing a plastic gear grease it is not only important to pay attention to compatibility.

-

Q Questions about…

AGear accuracy is mainly to control the accuracy of the transmission between gears during operation, such as: the smoothness of the transmission, the fluctuation of the instantaneous speed, if there is alternating reverse operation, whether its tooth side clearance reaches the minimum, if there is impact load, the accuracy should be slightly improved so as to reduce the damage brought to the gears by the impact load.

-

Q What are the ca…

APlastic gear units are generally only part of the machine and therefore the noise of the gear unit is part of the noise of the whole machine. In the case of installation bases and environmental influences, noise testing should be carried out under the specified testing conditions, in accordance with that.

-

Q What are the ad…

AWhat are the advantages and disadvantages of plastic gears? The advantages of plastic gears are ease of manufacture, low cost, high efficiency and corrosion resistance. The disadvantage is the strength. Generally applied in the force is not large or require transmission accuracy is not high, but also to control the cost of occasions.

-

Q What are the ma…

AFor the choice of datum, the choice of gear machining datum often differs depending on the structural shape of the gear. Gears with shafts are mainly positioned using vertex holes; for hollow shafts, the bevels of the two end holes are used after the central bore has been drilled; for large bore diameters, tapered plugs are used. The vertex positioning is highly accurate and allows for coincidence and uniformity of the benchmark.